Chapter : 1. Metals & Non Metals

Varieties of Iron

Varieties of Iron :

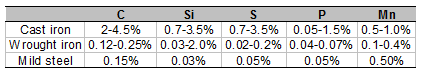

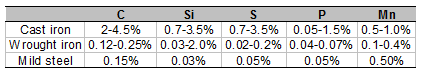

1. Pig iron and cast iron : The iron produced in the blast furnace is pig iron. It contains a comparatively high percentage of carbon due to which it is hard and brittle. It also contains phosphorus, silicon and manganese as impurities. Pig iron is melted, mixed with steel scrap and allowed to cool in moulds to give cast iron. Cast iron is impure iron, and is hard and brittle.

2. Wrought iron : It is almost a pure form of iron. It contains only 0.12% to 0.25% carbon. It melts at a higher temperature (1773 K) than that at which cast iron melts. Wrought iron is obtained by melting cast iron on a hearth lined with ferric oxide (Fe2O3) The impurities such as carbon, phosphorus, silicon and manganese are oxidized by Fe2O3

Fe2O3 + 3C → 2Fe + 3CO

Wrought iron is soft, grey and tough. It is malleable and ductile. Hence, it can be drawn into sheets and stretched into wires. It is used in making chains, wire, anchors and cores of electromagnets.

3. Steel : It is an alloy of iron and carbon. It contains about 0.15 to 1.7% of carbon. There are different types of steel.

(a) Mild steel : It contains less than 0.3% carbon. It is also called soft iron. Mild steel is used for making sheets and wires.

(b) Hard steel : It contains higher percentage (0.7-1.7%) of carbon. It is used in making tools and instruments.

(c) Alloy steels : Alloy steels are prepared by adding small amounts of nickel, cobalt, chromium, tungsten, molybdenum, manganese and silicon to steel. Alloy steels are used extensively in making rock-crushing machinery, helmets, armour plate, cutlery, springs, etc.

(d) Medium steel : It contains 0.3-D.7% carbon. It is hard and is used in making rails, bridges, etc.

1. Pig iron and cast iron : The iron produced in the blast furnace is pig iron. It contains a comparatively high percentage of carbon due to which it is hard and brittle. It also contains phosphorus, silicon and manganese as impurities. Pig iron is melted, mixed with steel scrap and allowed to cool in moulds to give cast iron. Cast iron is impure iron, and is hard and brittle.

2. Wrought iron : It is almost a pure form of iron. It contains only 0.12% to 0.25% carbon. It melts at a higher temperature (1773 K) than that at which cast iron melts. Wrought iron is obtained by melting cast iron on a hearth lined with ferric oxide (Fe2O3) The impurities such as carbon, phosphorus, silicon and manganese are oxidized by Fe2O3

Fe2O3 + 3C → 2Fe + 3CO

Wrought iron is soft, grey and tough. It is malleable and ductile. Hence, it can be drawn into sheets and stretched into wires. It is used in making chains, wire, anchors and cores of electromagnets.

3. Steel : It is an alloy of iron and carbon. It contains about 0.15 to 1.7% of carbon. There are different types of steel.

(a) Mild steel : It contains less than 0.3% carbon. It is also called soft iron. Mild steel is used for making sheets and wires.

(b) Hard steel : It contains higher percentage (0.7-1.7%) of carbon. It is used in making tools and instruments.

(c) Alloy steels : Alloy steels are prepared by adding small amounts of nickel, cobalt, chromium, tungsten, molybdenum, manganese and silicon to steel. Alloy steels are used extensively in making rock-crushing machinery, helmets, armour plate, cutlery, springs, etc.

(d) Medium steel : It contains 0.3-D.7% carbon. It is hard and is used in making rails, bridges, etc.

Trending Articles & Blogs

- Physics Tutor, Math Tutor Improve Your Child’s Knowledge

- How to Get Maximum Marks in Examination Preparation Strategy by Dr. Mukesh Shrimali

- 5 Important Tips To Personal Development Apply In Your Daily Life

- Breaking the Barriers Between High School and Higher Education

- 14 Vocational courses after class 12th

- Tips to Get Maximum Marks in Physics Examination

- Get Full Marks in Biology Class 12 CBSE

Download Old Sample Papers For Class X & XII

Download Practical Solutions of Chemistry and Physics for Class 12 with Solutions

Recent Questions Asked

- Newton’s laws of motion asked by Dr. Mukesh Shrimali

- Process of nutrition in Amoeba asked by Rajiv Sharma

- Importance of studying physics subject in school after 10th asked by Rajiv

- Refraction Through Prism in Different Medium asked by Kirti Sharma

- Ratio and Proportion Question asked by Education Desk

- Explain all the 12 tenses with example asked by Qwerty

- Refraction Through Prism in Different Medium asked by Seema Shrimali