Chapter : 1. Metals & Non Metals

Enrichment or dressing of an ore

Enrichment or dressing of an ore :

An ore mined from the earth's crust contains a number of impurities (gangue), which must be removed. The ore, free from gangue, then becomes suitable for subsequent treatment. Enrichment or dressing of an ore is carried out by the following methods.

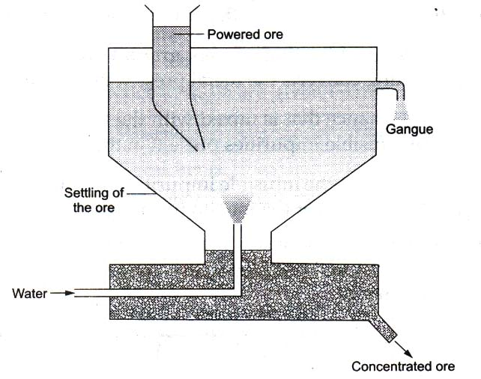

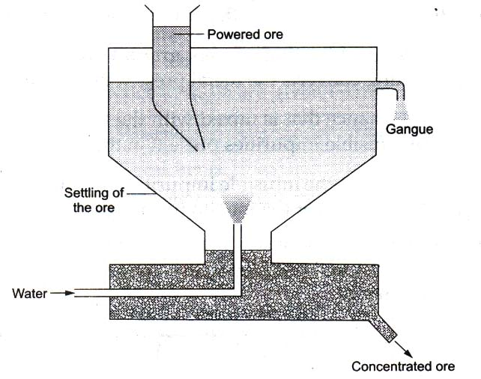

(i) Levigation : The powdered ore is washed in a jet of water. The lighter, rocky and earthy impurities are washed away by water, while heavier ore particles are left behind to settle down at the bottom. This process is also called hydraulic washing.

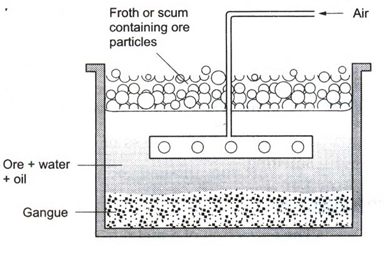

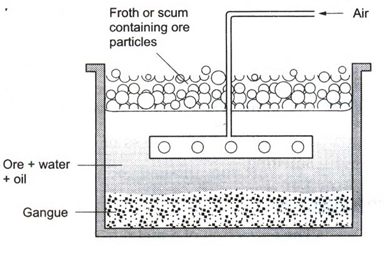

(ii) Froth floatation : Sulphide ores of copper, lead and zinc are generally concentrated by this method.

The finely powdered ore is mixed with water and a small amount of oil in a tank. Air is blown into the mixture. A froth or scum is produced at the surface. The ore particles are carried by the froth to the surface. The earthy impurities sink to the bottom. The froth along with the ore is removed. An acid is added to break up the froth. The concentrated ore is filtered and dried.

An ore mined from the earth's crust contains a number of impurities (gangue), which must be removed. The ore, free from gangue, then becomes suitable for subsequent treatment. Enrichment or dressing of an ore is carried out by the following methods.

(i) Levigation : The powdered ore is washed in a jet of water. The lighter, rocky and earthy impurities are washed away by water, while heavier ore particles are left behind to settle down at the bottom. This process is also called hydraulic washing.

(ii) Froth floatation : Sulphide ores of copper, lead and zinc are generally concentrated by this method.

The finely powdered ore is mixed with water and a small amount of oil in a tank. Air is blown into the mixture. A froth or scum is produced at the surface. The ore particles are carried by the froth to the surface. The earthy impurities sink to the bottom. The froth along with the ore is removed. An acid is added to break up the froth. The concentrated ore is filtered and dried.

Trending Articles & Blogs

- Physics Tutor, Math Tutor Improve Your Child’s Knowledge

- How to Get Maximum Marks in Examination Preparation Strategy by Dr. Mukesh Shrimali

- 5 Important Tips To Personal Development Apply In Your Daily Life

- Breaking the Barriers Between High School and Higher Education

- 14 Vocational courses after class 12th

- Tips to Get Maximum Marks in Physics Examination

- Get Full Marks in Biology Class 12 CBSE

Download Old Sample Papers For Class X & XII

Download Practical Solutions of Chemistry and Physics for Class 12 with Solutions

Recent Questions Asked

- Newton’s laws of motion asked by Dr. Mukesh Shrimali

- Process of nutrition in Amoeba asked by Rajiv Sharma

- Importance of studying physics subject in school after 10th asked by Rajiv

- Refraction Through Prism in Different Medium asked by Kirti Sharma

- Ratio and Proportion Question asked by Education Desk

- Explain all the 12 tenses with example asked by Qwerty

- Refraction Through Prism in Different Medium asked by Seema Shrimali